Steve Merritt at EPP shares some of the benefits of fully automated mixing systems, and highlights successful artisan bakery setups baking quality products at scale throughout Europe

The sales of artisan bread products continue to grow in the UK and Ireland, with the market seeing increasing consumer demand for high quality, flavourful products at scale. These breads frequently require a long resting phase, and as a result, it can be especially difficult for bakeries to scale up to meet demand.

This becomes particularly challenging when a significant increase in the dough throughput per hour is required. It has become more and more difficult to recruit a suitable workforce to carry out the level of work required,and manual processes risk leading to a lack of dough consistency and uniformity.

Fully automated industrial mixing solutions are the solution. They ensure consistent, repeatable dough production at scale. Our partner has installed a host of bespoke systems, tailored to the requirements of bakers, throughout Europe.

Automation to the rescue

Automated systems ensure dough consistency, allowing bakers to maximise yield and ROI. Dough is transported automatically either via an in-line system or a suspended shuttle. The chosen method depends on the application at hand.

All automated systems are carefully tailored to suit the requirements of each bakery.

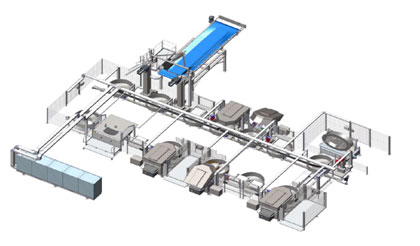

Figure1 is an example of a successful European bakery producing artisan bread at over three tonnes an hour.

Fig 1. A Bakery using five mixers

A bowl washing station is incorporated into this solution, ensuring mixing bowls can be automatically scheduled to be cleaned. With no need for removal or manual cleaning, leading to further savings, time and money.

Only one operator is required to run a system, placing minor ingredients into bowls (although it is also possible to fully automate this stage too) at the start and monitoring the automatic process.

It is also possible to achieve automation of an additional long fermentation stage with mixing bowls automatically stored in racks and then withdrawn for use in rotation.

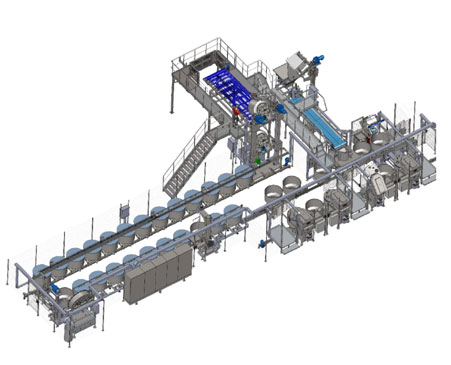

Fig 2.A bakery for artisan bread

Figure 2 is an example ofa very popular system for artisan bread. Operated manually, it would require at least five staff to move bowls from one station to another. Automation means that only one member of staff is required.

One carousel is used to weigh up ingredients and mix the dough. The second carousel is used for final resting after mixing. An elevator is used to automatically transfer the dough to the line.

This system is usually dedicated to run a recipe for an extended time, maximising efficiency, reducing downtime and cleaning.

These are just a couple of examples of the many highly productive automated systems working daily across Europe to create high quality baked goods. There is a wide array of customisation options, allowing for flexibility to create the perfect solution to create doughnuts, breads, pizza doughs, ‘rusks’ and much more.

Why invest?

When looking to upscale an artisan bakery, achieving product consistency is critical. An automated mixing solution that can mimic a traditional bakery process is essential to achieving this.

By investing in an automated system,bakeries can ensure constant high-quality production, with a much higher throughput than possible with manual methods. This consistency of dough in turn ensures other aspects of the bakery processes (such as dividing/rounding) also work optimally. Once the process is setup, very little additional work is required, with labour costs dramatically reduced.

Talk to EPP about your industrial mixing solution requirements today either by telephone 01372 745558 or e-mail sales@eppltd.co.uk or visit the website https://www.eppltd.co.uk/.