Depositing/Injecting/Decorating Lines

Correct handling and accuracy are critical for successful depositing solutions.

From fluid to viscous fillings, smooth whipped creams to fillings with inclusions, EPP offers systems that can handle any type of filling. Options include heated hoppers and stirrers for fillings that require controlled temperatures.

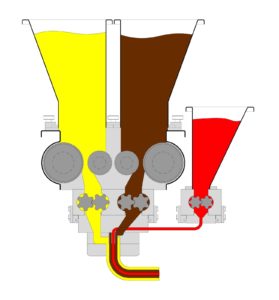

Lobe Depositors and Extruders: high capacity, individual lobe pump systems can produce plain, filled and decorated cookies, biscuits and fig bars. We have options for wire cut and smooth mix deposited biscuits as well as for the production of dual or tri-coloured filled biscuits simultaneously depositing two different doughs and a third, fluid filling. Sheeting brownies and flapjacks is also possible.

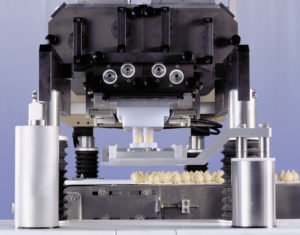

Volumetric Piston Depositor: accurate independent volumetric cylinders ensure accurate dosing to minimise waste, and servo-motor-driven heads increase precision and speed, offering accurate depositing and gentle handling of all types of doughs, mixes and batters for cakes, and fillings for pie shells.

Topping Depositor: systems available include spray heads, enrobers, piping systems, waterfall depositors, product dipping and decorating nozzle depositors for a wide range of toppings such as icing, chocolate, glazes or cream rosettes. A direct particulate depositing head and spreader is ideal for adding toppings – such as raspberries or streusel – to cakes, or for topping pizzas with diced ingredients such as cheese, ham or vegetables.

Filling Injection: for accurate injection of jam, ganache, cream or injecting bespoke fillings into muffins, Choux products, cakes or doughnuts; either from the top or from the side.

Depositors can be mounted in line for depositing cakes batters and pie fillings directly into tray indents. Units can be configured with a static or vertically moving head, or with a dual head for simultaneously depositing two different mixtures.

Depositing a wide range of batter mixes into cups or moulds, or jam, chocolate or other fillings into pie shells. Units can be configured with an optional control system to prevent product from being dosed if a cup is missing from the conveyor.

Individual depositors can be used as a flexible, versatile stand-alone machine, constructed on a C-shaped frame with single shoulder to enable seamless integration onto an existing production line or mounted directly on a tunnel oven band for high-capacity production.

The technology EPP offers effortlessly handles fluid, whipped or dense mixes and doughs with solid particles such as chocolate chips, candied fruit or nuts. Precise depositing, easy clean design and recipe storage features maximize quality, minimise down time and make switching between products quick and easy.

State-of-the-art automation ensures the highest quality, even at the most demanding throughput, and hygienic design allows efficient, effective cleaning during which the depositor can be taken away from the line, with reduced water usage. Equipment that offers optimum flexibility to enable fast switchover with minimum down time.

EPP has the experience to help you with your depositing and filling project to suit any type of batter and mix, and to handle and deposit the widest range of fillings, toppings, coatings and decoration. Call sales@eppltd.co.uk.