Bread Scoring Automation

EPP works with Beor, a company based in Barcelona (Spain) which has been designing and manufacturing industrial bakery equipment for many years. One of its divisions manufactures scoring systems suited to both fermented and non-fermented dough.

The products are scored by water jet, using a set of nozzles, and it offers some key advantages in comparison to scoring by metal blades:

- Smaller breads (up to 20 gr) can be scored without being moved

- No risk of blades breakage

- No risk of cutting for workers

- No downtime to change the blades

- Savings on blades

- Minimal amount of maintenance

Depending on the needs of the customer, Beor has developed different scoring applications, the most common of which are:

- CompactLeo: A semi-automatic scorer where the trays are fed manually into the machine.

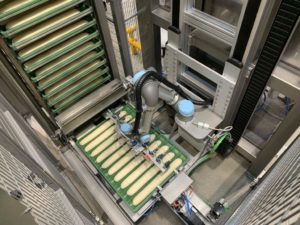

- Madrid: A semi-automatic scorer like the CompactLeo but in this case the bar with the nozzles is moved by a Collaborative Robot.

- Viena: A machine which scores automatically a rack in a 2 min and a half without the need of an operator.

- Bosnia: the score is totally automatic and made directly on the trays moved by a conveyor.

- New Jersey: A scorer installed on the infeed of a tunnel oven.

These systems are very flexible and easy to use. In order to ensure the perfect desired result, the score can be adjusted according to:

- Type: straight, inclined, crosswise and etc.

- Length and width

- Depth (depending on the pressure and speed)

- Height (distance between bread and nozzles)

- Jet inclination

In addition, the equipment has been tested to work with standard dough (as well as gluten free dough) with hydration levels from 50% to 95%. The trays/boards used during the scoring must be in very good condition and can be up to 1.000 x 1.000 mm in dixr.

Our experienced team at EPP can help you select the ideal scoring system for your needs.