Tunnel Ovens

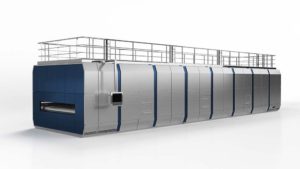

EPP’s extensive network of tunnel oven manufacturers ensures that we are able to offer you the right oven to meet your exact requirements.

With direct access to manufacturers, you will be able to see ovens being constructed, giving you unique insights and understanding, as well as being able to make use of superb test facilities for trials. We can also arrange visits to see installations in operation.

The main differentiating feature between tunnel ovens is the way that they transfer heat to the products. It is important to know the differences and the impact this has on the finished product.

Convection: Convection is the transfer of heat by air movement. A convection tunnel oven will offer similar baking characteristics to a rack oven, giving an even colouring of a product. Convection ovens are very versatile as you are able to adjust the amount of air movement and temperature independently, enabling a convection oven to successfully bake most product categories.

Thermal Radiation: Radiant heat transfer is the transfer of energy through the electromagnetic waves that are emitted by any material object as a consequence of its temperature. Radiant heat can seal the surface of a product and create a thick crust, locking in moisture in the product.

Hybrid: A hybrid oven is one that combines convection and radiation. This can be an oven that has two distinct heat transfer sections. For example, an oven for crackers would have a radiant first section to seal the surface and set the internal structure of the product, and then a convection back end to remove the moisture from the product. Another example of a hybrid oven is a single section that can change between convection and radiant or mixture of the two, massively increasing the product range that can be baked on a single oven, ensuring the oven is fit for future products yet to be developed.

The other main differentiating features between tunnel ovens are the types of conveyor used:

Grid – Ovens to bake products in tins or trays will have a heavy-duty conveyor to withstand the impact of the tins/trays. Grid conveyors often have a high free open area to allow the heat to be transferred through the conveyor from the heat source below.

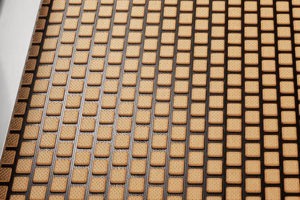

Mesh – A mesh conveyor is probably the most versatile type of conveyor as you can have products directly onto the mesh or place trays on it. There are many different types of mesh conveyors to suit the specific application. Biscuits are generally baked on mesh conveyors which leave distinctive patterns on the underside of the product.

Steel Band – These are used for products that are in direct contact with the conveyor, and would not be used to put tins or trays on the band. Steel bands offer high levels of conductive heat and are also used for biscuits, crackers and pastries.

Stones – Stones can be used as a conveyor within a fabricated carrier driven by chains. A stone conveyor replicates baking on the sole of a deck oven for high-capacity artisan bread plants.

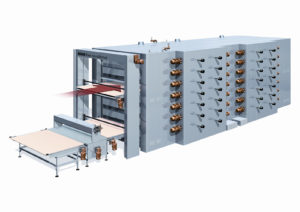

Tunnel ovens aren’t limited to being on a single level. If you need to maximise available space, EPP can provide solutions that have multiple levels (up to 6) with independent control of each deck.

There are many different factors when selecting the right oven for your production, and as such there is no hard and fast rule. Whatever you are looking to produce, whether it be tinned or artisan breads, pies, cakes, biscuits, or something else, EPP has experience to be able to select the right oven for you. Talk to the team about your project sales@eppltd.co.uk