Geary’s has quickly established itself as one of the UK’s best-loved bakery brands. Their Jason’s Sourdough is named after Jason Geary, the fourth generation Master Baker in the Geary family business, its product range includes popular delicacies such as ‘The Great White’, ‘Malted Majestic’ and ‘White Ciabattin’, a ciabatta-sourdough hybrid. European Process Plant (EPP) has supported its rapid expansion with a bespoke turnkey solution.

With the increasing demand for sourdough products, notably due to its positive associations with healthiness, taste and natural ingredients*, Geary’s aimed to boost production to keep up with consumer requirements. Having previously sought bakery machinery solutions from EPP since their product inception in 2019, Geary’s contacted EPP for a bespoke solution to increase production of ‘The Great White’.

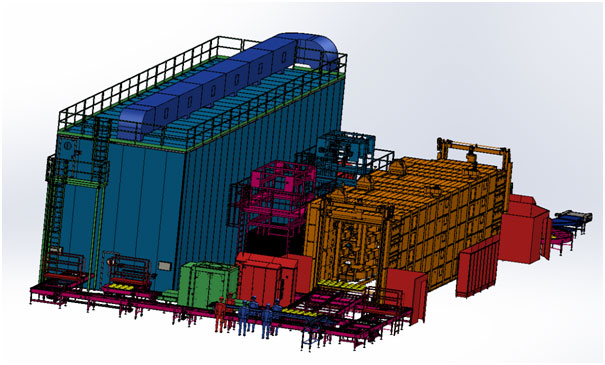

The turnkey integrated solution provided by EPP was customised to fit the space restrictions of a new, 800m² building. The solution comprises a prover, a robotic scoring unit and a five-deck Koenig tunnel oven as well as cooling and storing facilities.

With initial conversations taking place in October 2024, EPP organised trips to the Koenig Hungary test site which provided Geary’s with in-depth demonstrations of the machinery. A further trip to the Koenig site in Italy consolidated machinery choices .The layout of the bespoke turnkey solution was developed within three months of initial conversations, a testament to the great speed which EPP and Koenig were able to provide, with this process typically taking up to a year to create.

Additionally, the delivery and installation of the equipment can require nearly twelve months, however, with a deadline of 1st September 2025 for machinery to be up and running, the team will achieve this in just nine months, in time for the new launch deadlines within supermarkets.

Originally citing the requirement for semi-automatic solutions, Geary’s quickly recognised the potential of a fully automated solution which minimises labour, increases efficiency, and provides the capability to create eight thousand of its half-loaf sourdough products an hour.

As part of the solution, the five-deck Koenig tunnel oven, with its five levels, is a space-effective, gas fired solution with a total of fifteen burners which can each work independently from one another, for maximum versatility.

The robotic scoring unit is fully programmable, with the ability to change and create different scoring patterns. With different forms of scoring, the solution recommended for Geary’s utilises a spinning disk, to remove water elements which would remove flour from the product. “The equipment within this bespoke solution emphasises EPP’s ability to listen to the customer and in turn, recommend the right solution for their individual needs. Geary’s will be the first bakery in the UK to produce sourdough on this scale, and EPP is enthusiastic to be providing Geary’s with the solutions to achieve this” states Michael Lomas, Technical Sales Manager at EPP.

For more information on EPP and its wide range of products and services, please go to www.eppltd.co.uk.