Sourdough

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

EPP’s team works with you to ensure that we fully understand your requirements before making recommendations of equipment. It is only by understanding every stage of your process that we can ensure we can recommend the right equipment to meet your needs for your product(s), whether that is specifying ovens, dividers, or any of our established offering.

We work with our supplier partners to tailor a solution to suit your needs. We have the knowledge and capability of running trials and tests to ensure you have complete confidence in the solution you before you commit to your purchase. Drawing on a vast wealth of experience built up over the many projects we and our suppliers have been involved with both in the UK and around the world ensures that we can deliver on our promise.

Interested in new equipment? Get in touch

Keeping your equipment in top condition takes time and experience – our team of dedicated engineers have many years of experience between them which means that they can offer more than just mechanical repair.

They understand how the machines should be set up, how to make minor adjustments to improve performance, product quality and reduce waste. Our direct access to the machine designers and constructers ensures that we can get additional support if this is required.

If you have any questions, feel free to browse our FAQs section, or Get in touch

When parts wear out or break, it is reassuring to know that you are fitting parts to the specification of the Original Equipment Manufacturer.

By talking to our dedicated team, we can ensure that we provide you with the parts for your specific machine so that you can get back up and running as quickly as possible.

Interested in OEM parts? Get in touch

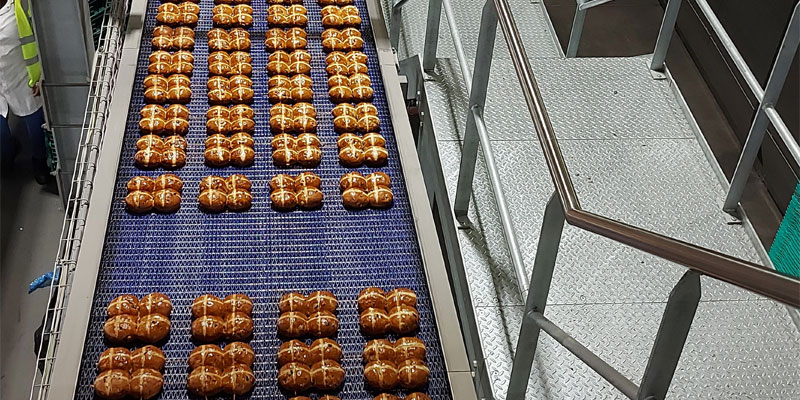

European Process Plant Ltd (EPP) is passionate about the industry and the people within it. EPP has helped bakers produce consistent, high quality goods with optimal efficiency, over five decades. By listening carefully to customers with care and attention along the journey, EPP supplies British and Irish bakers with new bakery equipment, provides ongoing servicing and support and OEM parts. The EPP team supports bakers through the process of acquiring high-quality bakery and food production equipment from its network of leading European manufacturing partners, including ingredient handling, mixers, dividers, depositors, ovens, coolers, slicers, wrappers, and everything in between. EPP works with all sizes of organisations across Britain and Ireland – from fledgling family artisan bakeries to established household name brands. Everyone is different, and so by working with you, EPP can offer a specialised solution to suit your needs and maximise both quality and efficiency. EPP is with its customers every step of the way.

Our unmatched relationships with top manufacturers allow us to specify the best equipment to suit your business requirements. The team at EPP will determine a solution to meet your bakery’s exact needs as well as designing, installing, and maintaining it for you.

EPP works closely with our manufacturers to develop new technological and innovative concepts and designs to meet our customers’ future production requirements. We’ll be there with you every step of the way!

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium.

Decades in business

manufacturers

key services

Main core of our company is our staff

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor.

“We’ve built up a good relationship with EPP, and they provided great support when we bought our oven which has been fantastic, so it seemed the logical decision to use them again.”

“EPP and Comas have both supported us brilliantly over the years. We know the people; we know the standards and the level of professionalism that they offer.”

“The relationship between EPP and N&H has been well established, having worked together for more than five years. EPP come to provide servicing – not just for the latest equipment, but also other bits of kit in the bakery – and they’ll give a good service to anything and everything. They’re also very good at getting our staff trained up quickly on the specifics of the equipment, which is very helpful.”